1.4. The Matmodlab Solution Method¶

Overview¶

Matmodlab exercises a material model directly by “driving” it through user specified paths. Matmodlab computes an increment in deformation for a given step and requires that the material model update the stress in the material to the end of that step.

The Role of the Material Model in Continuum Mechanics¶

Conservation Laws¶

Conservation of mass, momentum, and energy are the central tenets of the analysis of the response of a continuous media to deformation and/or load. Each conservation law can be summarized by the statement that the time rate of change of a quantity in a continuous body is equal to the rate of production in the interior plus flux through the boundary

Mathematically, the conservation laws for a point in the continuum are

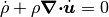

Conservation of mass

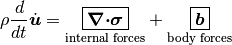

Conservtion of momentum per unit volume

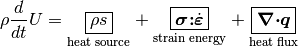

Conservation of energy per unit volume

where  is the displacement,

is the displacement,  the mass

density,

the mass

density,  the stress,

the stress,  the rate of strain,

the rate of strain,

the body force per unit volume,

the body force per unit volume,  the heat

flux,

the heat

flux,  the heat source, and

the heat source, and  is the internal energy

per unit mass.

is the internal energy

per unit mass.

In solid mechanics, mass is conserved trivially, and many problems are adiabatic or isotrhermal, so that only the momentum balance is explicitly solved

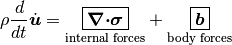

(1)

The balance of linear momentum is the continuum mechanics generalization of

Newton’s second law  .

.

The first term on the RHS of (1) represents the internal forces, which arise in the medium to resist imposed deformation. This resistance is a fundamental response of matter and is given by the divergence of the stress field.

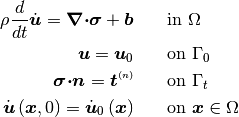

The balance of linear momentum represents an initial boundary value problem for applications of interest in solid dynamics:

(2)

The Finite Element Method¶

The form of the momentum equation in (2) is termed the strong form.

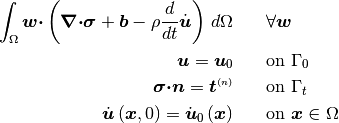

The strong form of the initial BVP problem can also be expressed in the weak

form by introducing a test function  and integrating

over space

and integrating

over space

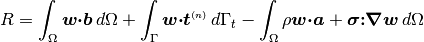

(3)

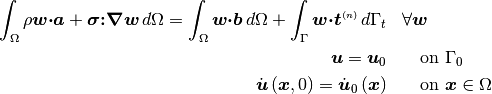

Integrating (3) by parts allows the traction boundary conditions to be incorporated in to the governing equations

(4)

This form of the IBVP is called the weak form. The weak form poses the IBVP as a integro-differential equation and eliminates singularities that may arise in the strong form. Traction boundary conditions are incorporated in the governing equations. The weak form forms the basis for finite element methods.

In the finite element method, forms of  are assumed in

subdomains (elements) in

are assumed in

subdomains (elements) in  and displacements are sought such that

the force imbalance

and displacements are sought such that

the force imbalance  is minimized:

is minimized:

(5)

The equations of motion as described in (5) are not closed, but

require relationships relating  to

to

Constitutive model  relationship between

relationship between

and

and

In the typical finite element procedure, the host finite element code passes to the constitutive routine the stress and material state at the beginning of a finite step (in time) and kinematic quantities at the end of the step. The constitutive routine is responsible for updating the stress to the end of the step. At the completion of the step, the host code then uses the updated stress to compute kinematic quantities at the end of the next step. This process is continued until the simulation is completed. The host finite element handles the allocation and management of all memory, including memory required for material variables.

Solution Procedure¶

In addition to providing a platform for material model developers to formulate and test constitutive routines, Matmodlab aims to provide users of material models an independent platform to exercise, parameterize, and compare material responses against single element finite element simulations. To this end, the solution procedure in Matmodlab is similar to that of the finite element method, in that the host code (Matmodlab) provides to the constitutive routine a measure of deformation at the end of a finite step and expects the updated stress in return. However, rather than solve the momentum equation at the beginning of each step and advancing kinematic quantities to the step’s end, Matmodlab retrieves updated kinematic quantities from user defined tables and/or functions.

The path through which a material is exercised is defined by piecewise continuous “steps” in which tensor components of stress and/or deformation are specified at discrete points in time. The components are used to obtain a sequence of piecewise constant strain rates that are used to advance the kinematic state. Supported components are strain, strain rate, stress, stress rate, deformation gradient, displacement, and velocity. “Mixed-modes” of strain and stress (and their rates) are supported. Components of displacement and velocity control are applied only to the “+” faces of a unit cube centered at the coordinate origin.

The Strain Tensor¶

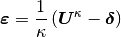

The components of strain are defined by

where  is the right Cauchy stretch tensor, defined by the

polar decomposition of the deformation gradient

is the right Cauchy stretch tensor, defined by the

polar decomposition of the deformation gradient  , and

, and  is a user specified

“Seth-Hill” parameter that controls the strain definition. Choosing

is a user specified

“Seth-Hill” parameter that controls the strain definition. Choosing

gives the Lagrange strain, which might be useful when testing

models cast in a reference coordinate system. The choice

gives the Lagrange strain, which might be useful when testing

models cast in a reference coordinate system. The choice  ,

which gives the engineering strain, is convenient when driving a problem over

the same strain path as was used in an experiment. The choice

,

which gives the engineering strain, is convenient when driving a problem over

the same strain path as was used in an experiment. The choice  corresponds to the logarithmic (Hencky) strain. Common values of

corresponds to the logarithmic (Hencky) strain. Common values of

and the associated names for each (there is some ambiguity in

the names) are listed in Table 1

and the associated names for each (there is some ambiguity in

the names) are listed in Table 1

|

Name(s) |

|---|---|

| -2 | Green |

| -1 | True, Cauchy |

| 0 | Logarithmic, Hencky, True |

| 1 | Engineering, Swainger |

| 2 | Lagrange, Almansi |

The volumetric strain ![\Strain[v]](../_images/math/6f72ba1c431cad365e8c617e03733d1b5426438a.png) is defined

is defined

(6)![\Strain[v] =

\begin{cases}

\OneOver{\kappa}\left(\Jacobian^{\kappa} - 1\right)

& \text{if }\kappa \ne 0 \\

\ln{\Jacobian} & \text{if }\kappa = 0

\end{cases}](../_images/math/e4500cb736e6dea360dd7d53e3b64a109b91c389.png)

where the Jacobian  is the determinant of the deformation gradient.

is the determinant of the deformation gradient.

Each step component, from time  to

to  is

subdivided into a user-specified number of “frames” and the material model

evaluated at each frame. When volumetric strain, deformation gradient,

displacement, or velocity are specified for a step, Matmodlab internally

determines the corresponding strain components. If a component of stress is

specified, Matmodlab determines the strain increment that minimizes the

distance between the prescribed stress component and model response.

is

subdivided into a user-specified number of “frames” and the material model

evaluated at each frame. When volumetric strain, deformation gradient,

displacement, or velocity are specified for a step, Matmodlab internally

determines the corresponding strain components. If a component of stress is

specified, Matmodlab determines the strain increment that minimizes the

distance between the prescribed stress component and model response.

Stress Control¶

Stress control is accomplished through an iterative scheme that seeks to

determine the unkown strain rates, ![\dStrain\,[\text{v}]](../_images/math/09e72411fada976599b42e00f59ab39e21a6d3a6.png) , that satisfy

, that satisfy

![\Stress\left(\dStrain\,[\text{v}]\right) = \PrescStress](../_images/math/d098820ed4f87ad152036b95f37f50743bc307cb.png)

where,  is a vector subscript array containing the components

for which stresses are prescribed, and

is a vector subscript array containing the components

for which stresses are prescribed, and  are the components

of prescribed stress.

are the components

of prescribed stress.

The approach is an iterative scheme employing a multidimensional Newton’s method. Each iteration begins by determining the submatrix of the material stiffness

![\Stiffness_{\text{v}} = \Stiffness\,[\text{v}, \text{v}]](../_images/math/fab547a0a662196f64bb6332413c8b91d2806877.png)

where  is the full stiffness matrix

is the full stiffness matrix

. The value of

. The value of

![\dStrain\,[\text{v}]](../_images/math/09e72411fada976599b42e00f59ab39e21a6d3a6.png) is then updated according to

is then updated according to

![\dStrain_{n+1}\,[\text{v}] =

\dStrain_{n}\,[\text{v}] -

\Stiffness_{\text{v}}^{-1}\DDotProd\Stress^{*}(\dStrain_{n}\,[\text{v}])/dt](../_images/math/7b685a01c4fdf4b05443c97759c78ba3e7c2ff91.png)

where

![\Stress^{*}(\dStrain\,[\text{v}]) = \Stress(\dStrain\,[\text{v}])

- \PrescStress](../_images/math/bb6190a142dbe02dad786a9dfd5ae5c56943d3d0.png)

The Newton procedure will converge for valid stress states. However, it is possible to prescribe invalid stress state, e.g. a stress state beyond the material’s elastic limit. In these cases, the Newton procedure may not converge to within the acceptable tolerance and a Nelder-Mead simplex method is used as a back up procedure. A warning is logged in these cases.

The Material Stiffness¶

As seen in Stress Control, the material tangent stiffness matrix, commonly referred

to as the material’s “Jacobian”, plays an integral roll in the solution of the

inverse stress problem (determining strains as a function of prescribed

stress). Similarly, the Jacobian plays a role in implicit finite element

methods. In general, the Jacobian is a fourth order tensor in  with 81 independent components. Casting the stress and strain second order

tensors in

with 81 independent components. Casting the stress and strain second order

tensors in  as first order tensors in

as first order tensors in  and the

Jacobian as a second order tensor in

and the

Jacobian as a second order tensor in  , the stress/strain relation

in Stress Control can be written in matrix form as

, the stress/strain relation

in Stress Control can be written in matrix form as

![\begin{Bmatrix}

\dStress[11] \\

\dStress[22] \\

\dStress[33] \\

\dStress[12] \\

\dStress[23] \\

\dStress[13] \\

\dStress[21] \\

\dStress[32] \\

\dStress[31]

\end{Bmatrix} =

\begin{bmatrix}

C_{1111} & C_{1122} & C_{1133} & C_{1112} & C_{1123} & C_{1113} & C_{1121} & C_{1132} & C_{1131} \\

C_{2211} & C_{2222} & C_{2233} & C_{2212} & C_{2223} & C_{2213} & C_{2221} & C_{2232} & C_{2231} \\

C_{3311} & C_{3322} & C_{3333} & C_{3312} & C_{3323} & C_{3313} & C_{3321} & C_{3332} & C_{3331} \\

C_{1211} & C_{1222} & C_{1233} & C_{1212} & C_{1223} & C_{1213} & C_{1221} & C_{1232} & C_{1231} \\

C_{2311} & C_{2322} & C_{2333} & C_{2312} & C_{2323} & C_{2313} & C_{2321} & C_{2332} & C_{2331} \\

C_{1311} & C_{1322} & C_{1333} & C_{1312} & C_{1323} & C_{1313} & C_{1321} & C_{1332} & C_{1331} \\

C_{2111} & C_{2122} & C_{2133} & C_{2212} & C_{2123} & C_{2213} & C_{2121} & C_{2132} & C_{2131} \\

C_{3211} & C_{3222} & C_{3233} & C_{3212} & C_{3223} & C_{3213} & C_{3221} & C_{3232} & C_{3231} \\

C_{3111} & C_{3122} & C_{3133} & C_{3312} & C_{3123} & C_{3113} & C_{3121} & C_{3132} & C_{3131}

\end{bmatrix}

\begin{Bmatrix}

\dStrain[11] \\

\dStrain[22] \\

\dStrain[33] \\

\dStrain[12] \\

\dStrain[23] \\

\dStrain[13] \\

\dStrain[21] \\

\Strain[32] \\

\dStrain[31]

\end{Bmatrix}](../_images/math/021283df98fb20b912d75fdf80b9ba55be9d8e53.png)

Due to the symmetries of the stiffness and strain tensors (![\Stiffness[ijkl]=\Stiffness[ijlk]](../_images/math/27a613d00031e191d6a9e74a65984ad4c0d18f2a.png) ,

, ![\dStrain[ij]=\dStrain[ji]](../_images/math/73873ff92a73ea887fe6cecacfc0a2ef388cc422.png) ), the expression above can be simplified by removing the last three columns of

), the expression above can be simplified by removing the last three columns of  :

:

![\begin{Bmatrix}

\dStress[11] \\

\dStress[22] \\

\dStress[33] \\

\dStress[12] \\

\dStress[23] \\

\dStress[13] \\

\dStress[21] \\

\dStress[32] \\

\dStress[31]

\end{Bmatrix} =

\begin{bmatrix}

C_{1111} & C_{1122} & C_{1133} & C_{1112} & C_{1123} & C_{1113} \\

C_{2211} & C_{2222} & C_{2233} & C_{2212} & C_{2223} & C_{2213} \\

C_{3311} & C_{3322} & C_{3333} & C_{3312} & C_{3323} & C_{3313} \\

C_{1211} & C_{1222} & C_{1233} & C_{1212} & C_{1223} & C_{1213} \\

C_{2311} & C_{2322} & C_{2333} & C_{2312} & C_{2323} & C_{2313} \\

C_{1311} & C_{1322} & C_{1333} & C_{1312} & C_{1323} & C_{1313} \\

C_{2111} & C_{2122} & C_{2133} & C_{2212} & C_{2123} & C_{2213} \\

C_{3211} & C_{3222} & C_{3233} & C_{3212} & C_{3223} & C_{3213} \\

C_{3111} & C_{3122} & C_{3133} & C_{3112} & C_{3123} & C_{3113}

\end{bmatrix}

\begin{Bmatrix}

\dStrain[11] \\

\dStrain[22] \\

\dStrain[33] \\

2\dStrain[12] \\

2\dStrain[23] \\

2\dStrain[13]

\end{Bmatrix}](../_images/math/fbc1cc8c7082ba95ba34c70007c410f6ceee7cba.png)

Considering the symmetry of the stress tensor (![\dStress[ij]=\dStress[ji]](../_images/math/6313a1bbe776711c9ba5f0d03062767a0b15511a.png) ) and the major symmetry of

) and the major symmetry of  (

(![\Stiffness[ijkl]=\Stiffness[klij]](../_images/math/bce7222a69dc23a6338105c3066cb5b9e356cf7b.png) ), the final three rows of

), the final three rows of  may also be ommitted, resulting in the symmetric form

may also be ommitted, resulting in the symmetric form

![\begin{Bmatrix}

\dStress[11] \\

\dStress[22] \\

\dStress[33] \\

\dStress[12] \\

\dStress[23] \\

\dStress[13]

\end{Bmatrix} =

\begin{bmatrix}

C_{1111} & C_{1122} & C_{1133} & C_{1112} & C_{1123} & C_{1113} \\

& C_{2222} & C_{2233} & C_{2212} & C_{2223} & C_{2213} \\

& & C_{3333} & C_{3312} & C_{3323} & C_{3313} \\

& & & C_{1212} & C_{1223} & C_{1213} \\

& & & & C_{2323} & C_{2313} \\

symm & & & & & C_{1313} \\

\end{bmatrix}

\begin{Bmatrix}

\dStrain[11] \\

\dStrain[22] \\

\dStrain[33] \\

2\dStrain[12] \\

2\dStrain[23] \\

2\dStrain[13]

\end{Bmatrix}](../_images/math/751657b328d9985f1ea41614a881677f3fbf2684.png)

Letting ![\{\dStress[1],\dStress[2],\dStress[3], \dStress[4], \dStress[5], \dStress[6]\}= \{\dStress[11],\dStress[22],\dStress[33], \dStress[12],\dStress[23],\dStress[13]\}](../_images/math/768a9e25d288dd4337e5524dfa2d777dc7a4d106.png) and

and ![\{\dStrain[1],\dStrain[2],\dStrain[3], \dot{\gamma_4}, \dot{\gamma_5}, \dot{\gamma_6}\}= \{\dStrain[11],\dStrain[22],\dStrain[33],2\dStrain[12],2\dStrain[23],2\dStrain[13]\}](../_images/math/c2488e180e4a35c607acedab6b42301297698333.png) , the above stress-strain relationship is re-written as

, the above stress-strain relationship is re-written as

![\begin{Bmatrix}

\dStress[1] \\

\dStress[2] \\

\dStress[3] \\

\dStress[4] \\

\dStress[5] \\

\dStress[6]

\end{Bmatrix} =

\begin{bmatrix}

C_{11} & C_{12} & C_{13} & C_{14} & C_{15} & C_{16} \\

& C_{22} & C_{23} & C_{24} & C_{25} & C_{26} \\

& & C_{33} & C_{34} & C_{35} & C_{36} \\

& & & C_{44} & C_{45} & C_{46} \\

& & & & C_{55} & C_{56} \\

symm & & & & & C_{66} \\

\end{bmatrix}

\begin{Bmatrix}

\dStrain[1] \\

\dStrain[2] \\

\dStrain[3] \\

\dot{\gamma_4} \\

\dot{\gamma_5} \\

\dot{\gamma_6}

\end{Bmatrix}](../_images/math/9531674545abc3696b77e6bab94a6ce89476e48b.png)

As expressed, the components of  and

and  are first order tensors and

are first order tensors and  is a second order tensor in

is a second order tensor in  , respectively.

, respectively.

Alternative Representations of Tensors in  ¶

¶

The representation of symmetric tensors at the end of The Material

Stiffness is known as the “Voight” representation. The shear strain

components ![\dStrain[I]=2\dStrain[ij], \ I=4,5,6, \ ij=12,23,13](../_images/math/6d164a7f981fde228dc164752ad29dd00cfc0a9d.png) are

known as the engineering shear strains (in contrast to

are

known as the engineering shear strains (in contrast to ![\dStrain[ij], \

ij=12,23,13](../_images/math/636e506d88a204e0ef976dea078d9cdf2a1bd834.png) which are known as the tensor components). An advantage of the

Voight representation is that the scalar product

which are known as the tensor components). An advantage of the

Voight representation is that the scalar product

![\Stress[ij]\dStrain[ij]=\Stress[I]\dStrain[I]](../_images/math/1120fa3dc32feadcc9e367bdeb6253b6395d6140.png) is preserved and the

components of the stiffness tensor are unchanged in

is preserved and the

components of the stiffness tensor are unchanged in  . However,

one must take care to account for the factor of 2 in the engineering shear

strain components.

. However,

one must take care to account for the factor of 2 in the engineering shear

strain components.

Alternatively, one can express symmetric second order tensors with their

“Mandel” components

![\{\AA[1],\AA[2],\AA[3],\AA[4],\AA[5],\AA[6]\}=\{\AA[11],\AA[22],\AA[33],

\sqrt{2}\AA[12],\sqrt{2}\AA[23],\sqrt{2}\AA[13]\}](../_images/math/c404fcff4fb057d49a4fa38dc3f031b5f7561088.png) . Representing both the stress and strain with their Mandel representation also preserves the scalar product, without having to treat the components of stress and strain differently (at the expense of carrying around the factor of

. Representing both the stress and strain with their Mandel representation also preserves the scalar product, without having to treat the components of stress and strain differently (at the expense of carrying around the factor of  in the off-diagonal components of both). The Mandel representation has the advantage that its basis in

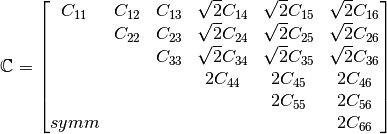

in the off-diagonal components of both). The Mandel representation has the advantage that its basis in  is orthonormal, whereas the basis for the Voight representation is only orthogonal. If Mandel components are used, the components of the stiffness must be modified as

is orthonormal, whereas the basis for the Voight representation is only orthogonal. If Mandel components are used, the components of the stiffness must be modified as